BEHIND THE SCENES: HOW WE ENSURE OUR MOBILE ROBOTIC SYSTEM IS READY FOR THE REAL WORLD

- antonzaitsev4

- Jun 16, 2025

- 3 min read

Updated: Jul 29, 2025

When you're investing in a mobile robotic system—especially one designed for high-precision tasks like drilling—confidence in its performance is everything. Whether you're integrating it into a tunnel construction project or exploring ways to automate your drilling process, you want proof that the technology works before it ever hits the field.

That's where acceptance testing comes in.

What Is Acceptance Testing?

In simple terms, acceptance testing is how we make sure our system performs exactly as promised. After passing our stringent functional safety testing, this is the final critical step before approval and deployment. Every system must pass the acceptance test — no exceptions. This isn’t just about flipping switches and checking boxes—it’s a rigorous, real-world simulation of how our system will behave in complex environments, like the dynamic and often unforgiving conditions of a construction site. And when the system is delivered to a customer, these tests serve as the formal basis for their acceptance

We’re excited to give you a behind-the-scenes look at what that process involves—and why it matters to you.

The Goal: Prove It Works. Precisely.

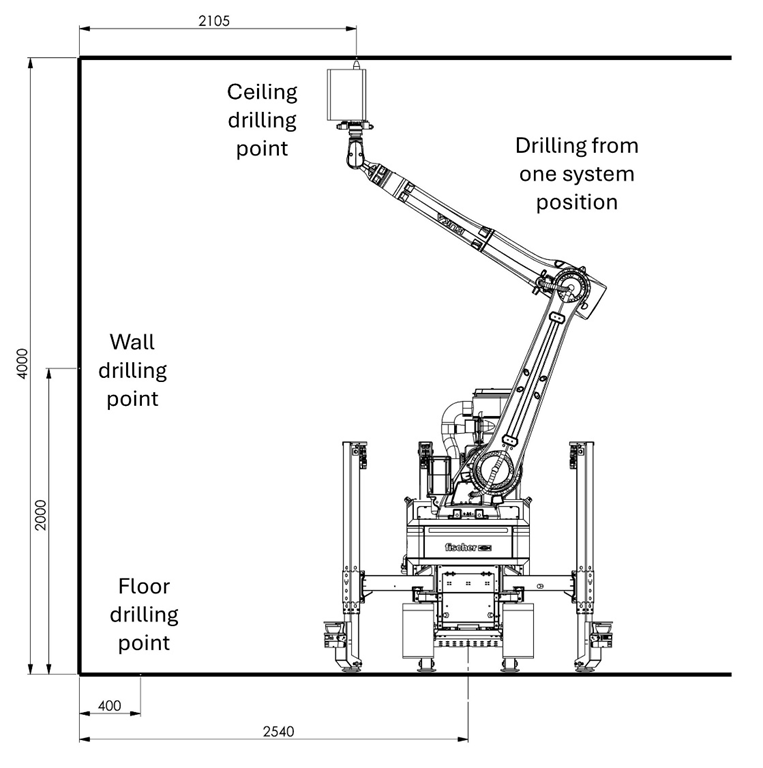

Our robotic system, MRS15, is designed to drill holes of specific diameters, at specific angles, in a variety of positions and orientations. To validate its capabilities, we conduct a series of structured test cases that focus on:

Safety: Does MRS15 pass our comprehensive functional safety tests?

Functionality: Can MRS15 carry out the full drilling cycle under real-world constraints?

Reachability: Can it physically get to the spots it needs to?

Accuracy & Repeatability: Does it consistently drill where it's supposed to?

Tolerance Verification: Are hole diameters, depths, and angles within spec?

Each of these criteria isn’t just a feature—it's a promise. And we set out to prove that our system can keep that promise under pressure.

The Setup: Simulating the Real World

To make the tests meaningful, we created a controlled environment that simulates the conditions of a tunnel construction site. Within this setup, we run three major test cases, each designed to evaluate different aspects of the robot’s performance. Between each test, MRS15 is being repositioned to simulate real-world movement and setup changes.

The Test Cases: Real-World Scenarios

Test Case 1: Hole Depth and Local Accuracy

In the first scenario, we assess:

How accurately the system can drill to a specified hole depth

The relative positioning of holes from a single waypoint

This test ensures that, from one position, the robot can consistently create a precise hole pattern.

Test Case 2: Reach Capability

Here, we push the system to its physical limits by placing drilling targets across a broad area to see:

Whether the robot can physically reach all required positions

How it maintains precision over distance

For operations which require high accuracy at a distance—like warehouses or tunnels—this is key.

Test Case 3: Accuracy Across Waypoints

This scenario tests the robot's ability to reposition and still maintain accuracy. We measure:

Relative accuracy of hole positions across multiple robot movements

Absolute accuracy of each drill hole compared to its ideal target

It’s not enough for a robot to be accurate from one spot—it has to stay accurate as it moves. This test proves that our system can reposition and still deliver a hole pattern with pinpoint precision.

The Outcome: Ready for the Field

These tests aren’t just internal checklists—they’re a formal part of how we confirm that the system is ready for final approval and deployment. We analyse the data, verify that every performance metric meets or exceeds requirements, and document the results.

For our latest test, MRS15 delivered on all fronts.

Test Case 1 Procedure

Test Case 2 Procedure

Test Case 3 Procedure

Why This Matters to You

If you're considering our mobile robotic system for your project, acceptance testing is your assurance that:

The system performs as advertised

It's been tested under conditions that reflect your real-world environment

It delivers the precision, flexibility, and reliability you need

Whether you’re drilling in a warehouse, on a bridge or in a remote tunnel, you can be confident that our system is ready to go the distance—and do it accurately.

Want to see the data? We’re happy to share more details from our acceptance testing process. Reach out to our sales team to start a conversation about how MRS15 could fit into your project.